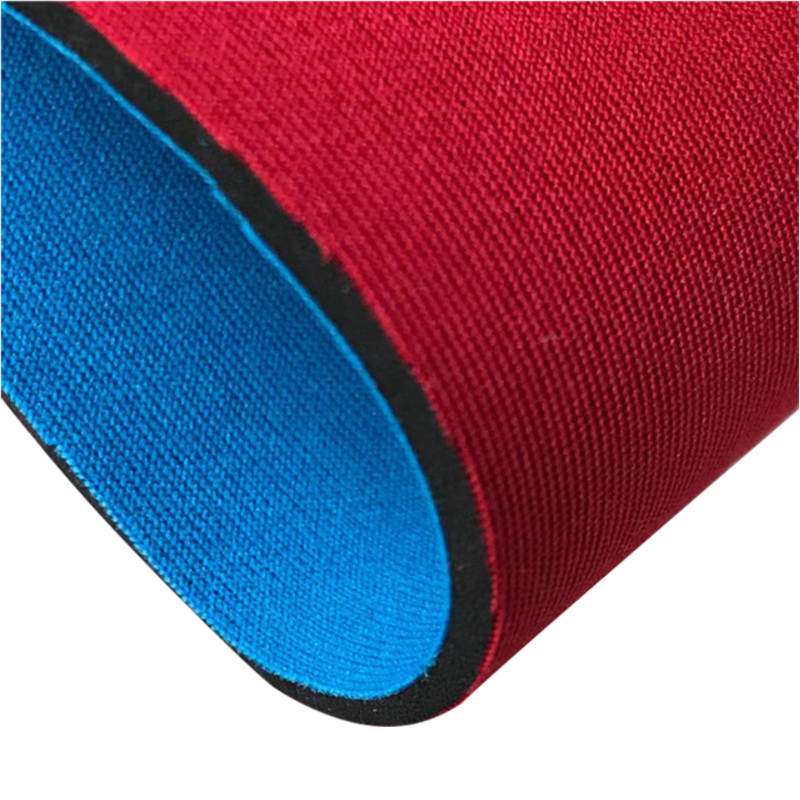

Neoprene Fabric

WT005

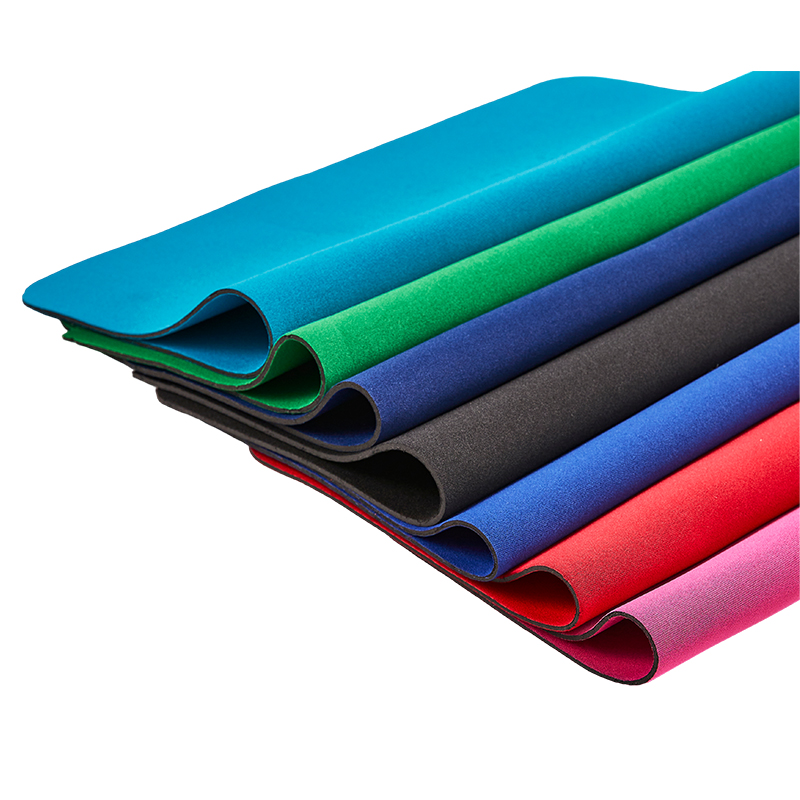

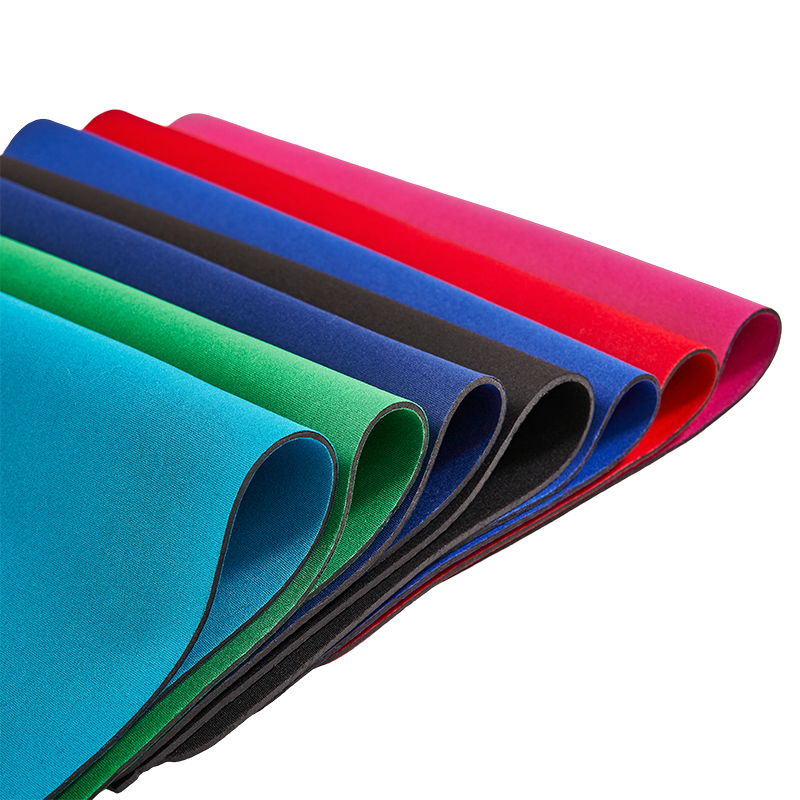

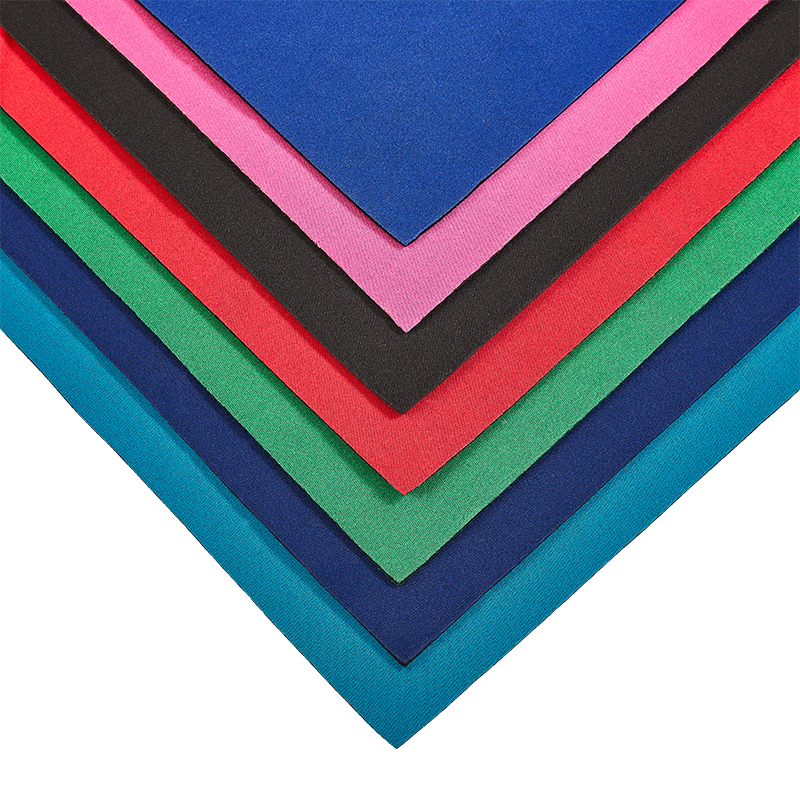

Neoprene classification: SBR SCR CR Hardness: 0-3 degrees 6-8 degrees 9-11 degrees 12-16 degrees Fabric type: 1. Polyester nylon cotton knitted 2. Lycra fabric 3. OK cloth mercerized cloth terry cloth 4. Mesh fabric leather fabric Color: black off-white Sheet size: 1.3*3.3 meters Roll size: calculated according to thickness Fabric color: can be selected from pantone color card or from our inventory Thickness: 1-50mm Application: bags, shoes, covers, sportswear, swimming trunks, diving suits, surfing suits, gloves, sports protective gear, medical protective gear, pet supplies, fishing gear supplies, etc. Sample: 1-2 days 0.5 meters free of charge Bulk order: 3-5 days Packaging method; roll packaging with cardboard tube + waterproof plastic bag + tear-resistant nylon bag.

1. Neoprene fabrics can protect products and prevent wear and tear.

2. The materials used in neoprene are elastic and reduce damage to products caused by collisions.

3. Neoprene is light and comfortable, and can also be carried alone.

4. Neoprene has a fashionable appearance design.

5. Neoprene does not deform after long-term use.

6. Neoprene is dustproof, anti-static, and scratch-resistant.

7. Neoprene is waterproof and breathable and can be washed repeatedly.

SBR rubber: SBR SCR CR neoprene is sold directly by the manufacturer, and samples can be provided free of charge, with a thickness of 0.08mm-40mm.

Composite fabrics: N cloth, T cloth, Lycra cloth, Velcro cloth, Mercerized cloth, OK cloth, and Jiaji cloth.

Composite process: water-based glue, elastic glue, PUR hot melt glue, toluene-resistant waterproof, embossing, punching, and cutting on a cutting bed.

Characteristics of diving materials: wear-resistant, waterproof, shock-absorbing, heat-insulating, elastic, impact-resistant.

Scope of application: luggage, handbags, sports protective gear, medical protective gear, children's school bags, cup covers, bottle covers, diving suits, surfing suits.

Core advantages of products: comprehensive coverage of material characteristics and customization capabilities

Neoprene Fabric takes "high elasticity, waterproofness, and durability" as its core, combines diversified classification and customization services, and provides precise material solutions for different industries:

1. High-quality materials, excellent performance

Basic characteristics: Neoprene material has natural advantages:

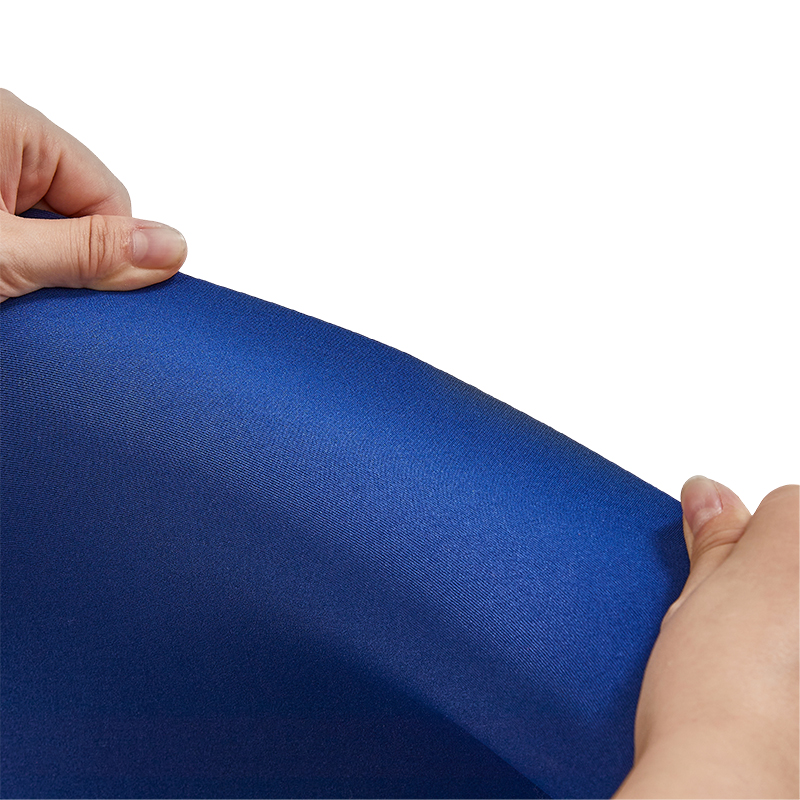

High elasticity and flexibility: It can be stretched to several times its original length and then rebound quickly, suitable for scenes such as underwear and sports protective gear that need to fit the human body;

Waterproof and anti-fouling: The surface is dense and waterproof, effectively blocking water penetration, suitable for water sports equipment such as diving suits and surfing suits;

Weather resistance and durability: Tear resistance, anti-aging, can maintain stable performance in an environment of -40℃ to 120℃, and extend the service life of the product;

Environmental protection and safety: Some models have passed international environmental certification (such as REACH, ROHS), and meet food contact or medical grade standards (need to be confirmed according to the specific model).

2. Multiple classifications, precise adaptation to needs

Classification by ingredients:

SBR (styrene butadiene rubber): economical choice, cost-effective, suitable for general cost-sensitive scenarios (such as ordinary bags and shoes);

SCR (blend of chloroprene rubber and styrene butadiene rubber): balances elasticity and cost, suitable for medium-strength protection scenarios (such as sports gloves and pet pads);

CR (pure chloroprene rubber): a high-performance representative, oil-resistant and chemical-resistant, suitable for high-demand scenarios such as medical protective gear and industrial gloves.

Classification by hardness:

0-3 degrees: ultra-soft material, soft touch, suitable for underwear (such as swimwear, sports bras), baby products;

6-8 degrees: medium hardness, taking into account elasticity and support, suitable for sports knee pads and wrist guards;

9-11 degrees: relatively hard material, wear-resistant and impact-resistant, suitable for bags, shoes and other products that require structural support;

12-16 degrees: high-hardness material, high strength, can be used for industrial protective equipment (such as anti-cut gloves, fishing pants support layer).

3. Various fabric types to meet diverse designs

Supports 4 major types of fabric bases to meet different product styles and functional requirements:

Polyester nylon cotton knitted: Balanced breathability and elasticity, suitable for sportswear and casual bags;

Lycra fabric: Super elastic and close-fitting, used in swimwear and tight sportswear to improve freedom of movement;

OK cloth/mercerized cloth/terry cloth: OK cloth has a smooth surface and is easy to clean (suitable for medical protective gear); mercerized cloth has a high-grade texture (suitable for fashionable bags); terry cloth absorbs sweat and dries quickly (suitable for sports headbands and wristbands);

Mesh cloth/leather fabric: Mesh cloth is breathable and heat-dissipating (suitable for summer sports equipment); leather fabric improves texture (suitable for fashionable shoes and high-end bags).

4. Flexible customization, satisfying both brand and function

Color customization: Provide basic colors such as black and beige, and support customized exclusive colors (such as brand standard colors, seasonal theme colors) according to Pantone color cards, or choose from existing stock colors;

Thickness customization: Covering the range of 1-50mm ultra-thin to ultra-thick, suitable for diverse needs from thin swimsuits (1-3mm) to thick diving suits (8-10mm), industrial protective pads (20-50mm), etc.;

Flexible size: Sheet size 1.3*3.3 meters (suitable for small batch proofing), coiled material calculated by thickness (supporting large-scale production), reducing customer inventory pressure.

Application scenarios: From sports and outdoor to industrial medical care, covering the needs of the entire industry

1. Sports and outdoor field: core materials for function and experience

Water sports: diving suits, surfing suits, and swimming trunks use CR-type high-elastic waterproof fabrics with a thickness of 8-10mm to effectively isolate cold water and keep the body flexible;

Land sports: yoga suits and cycling pants use Lycra-based ultra-thin fabrics (1-3mm), which fit the body and are breathable and perspiration-wicking; sports protective gear (knee pads, elbow pads) use SCR-type medium-hardness fabrics (6-8mm) to provide support and cushioning;

Outdoor equipment: mountaineering bags and hiking shoes use SBR-type wear-resistant fabrics (9-11mm) to enhance the tear resistance of the bag body/shoe surface and adapt to complex outdoor environments.

2. Fashion apparel: innovative carrier of texture and design

Swimwear/sportswear: polyester nylon cotton knitted base + bright Pantone colors, taking into account elasticity and fashion sense, meeting the dual needs of young consumers for "function + appearance";

Fashion bags: leather fabric + mesh fabric splicing design, improving the texture and breathability of bags, suitable for spring and summer products of trendy brands.

3. Industrial medical field: professional choice for safety and protection

Medical protective gear: OK cloth base + CR type ultra-soft fabric (0-3mm), skin-friendly, breathable and easy to clean, suitable for postoperative rehabilitation protective gear and joint support belts;

Industrial protection: SCR type medium hardness fabric (9-11mm) is used for anti-cut gloves and anti-slip shoes, CR type high hardness fabric (12-16mm) is used for mechanical operation protective pads to resist oil and impact.

4. Pet and fishery fields: practical and durable double guarantee

Pet products: towel cloth base + SBR type fabric (6-8mm), sweat-absorbing, quick-drying and wear-resistant, suitable for pet pads and traction ropes;

Fishing equipment: CR type waterproof fabric (8-10mm) is used for fishing pants and fishing net protective covers to resist seawater erosion and daily wear.

Our advantages: source manufacturers, professional and efficient dual drive

As a source manufacturer focusing on the production of neoprene fabrics, we provide full-link support:

Quick response and flexible customization:

Sample service: 1-2 days fast proofing, free within 0.5 meters (reducing customer trial and error costs);

Small batch support: no minimum order quantity (MOQ), suitable for new product development and small batch customization;

Bulk delivery: regular orders are shipped in 3-5 days, urgent orders can be negotiated to expedite, to meet the market's demand for rapid response.

Balance between quality and cost:

Controllable materials: Control the entire process from raw material procurement to finished product production to ensure that indicators such as hardness, elasticity, and waterproofness meet the standards;

Price advantage: Large-scale production + direct supply from the source, while ensuring quality, providing competitive prices that are 15%-20% lower than peers;

Professional team and reliable packaging:

Technical team: With more than 5 years of experience in the research and development of chloroprene rubber materials, we can provide material selection and process optimization suggestions;

Packaging guarantee: The coiled material is packaged in three layers of "pallet tube + waterproof plastic bag + tear-resistant nylon bag" to ensure that it is not damaged during transportation.