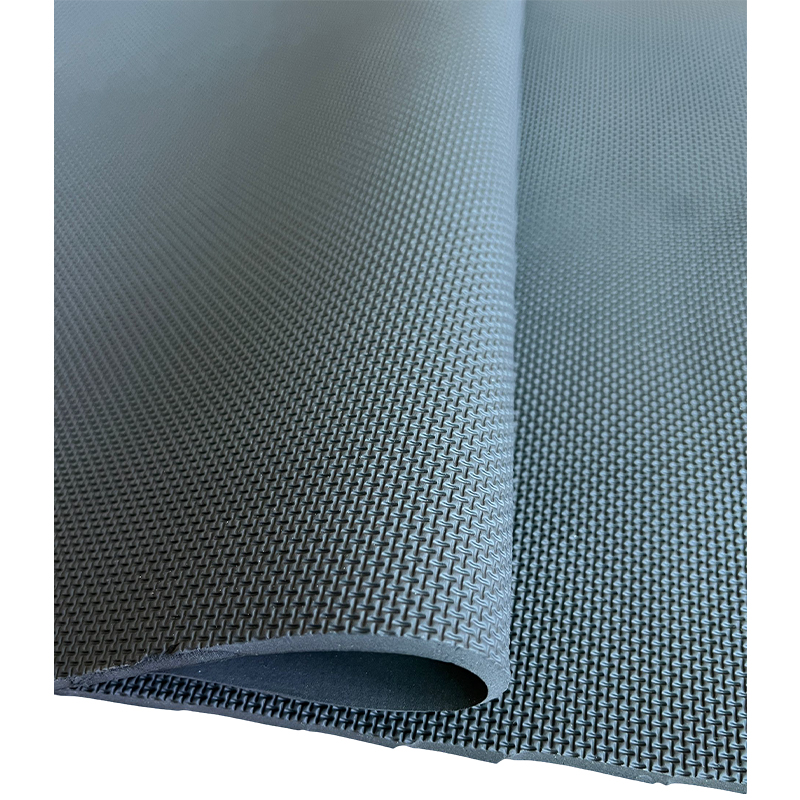

Neoprene SBR Embossed

WT006

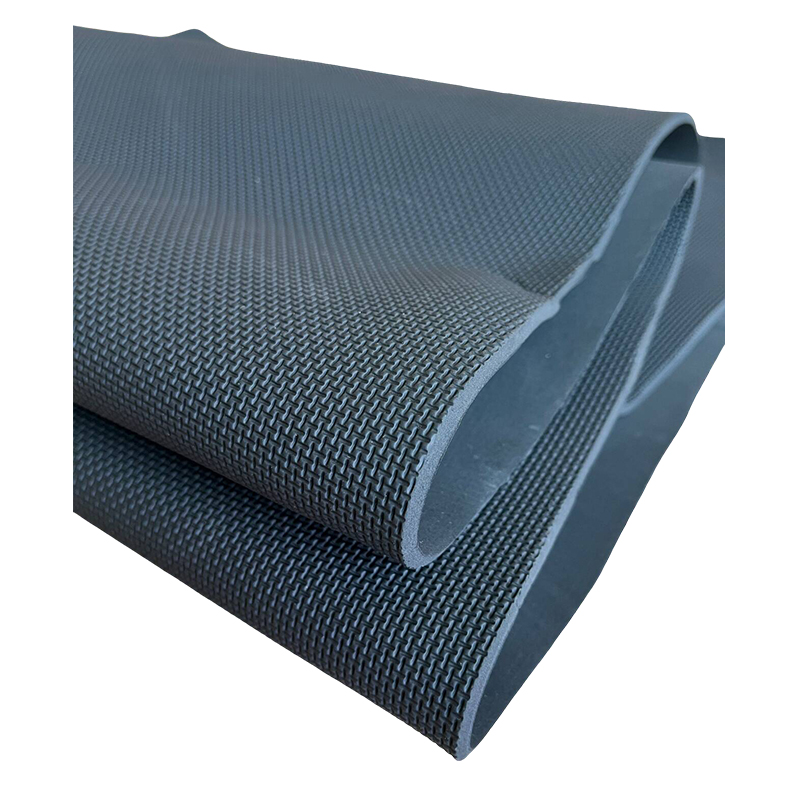

Neoprene classification: SBR SCR CR Hardness: 0-3 degrees 6-8 degrees 9-11 degrees 12-16 degrees Fabric type: 1. Polyester nylon cotton knit 2. Lycra fabric 3. OK cloth mercerized cloth terry cloth 4. Mesh fabric leather fabric Color: black off-white Sheet size: 1.3*3.3 meters Embossing shape: coarse embossing fine embossing Roll size: calculated according to thickness Fabric color: You can choose from the pantone color card or from our stock Thickness: 1-50mm Application: bags, shoes, sportswear, swimming trunks, diving suits, surfing suits, gloves, sports protective gear, medical protective gear, pet supplies, fishing gear, etc. Sample: 1-2 days 0.5 meters provided free of charge Bulk order: 3-5 days Packing method; roll packaging with cardboard tube + waterproof plastic bag + tear-resistant nylon bag

Core advantages of the product: economical SBR material + functional embossing process, creating a cost-effective customized solution

Neoprene SBR Embossed takes "economical and practical, embossing energy enhancement" as the core, combining the low-cost advantage of SBR type chloroprene rubber with the functionality of coarse/fine embossing process, to provide material solutions with both performance and design for bags, shoes, sportswear and other scenes:

1. Basic material: SBR type chloroprene rubber, economical first choice

Composition characteristics: using styrene butadiene rubber (SBR) as the main material, balancing performance and cost, suitable for price-sensitive but basic waterproof and elastic scenes (such as ordinary bags, shoe linings);

Core advantages: Compared with SCR/CR type, SBR has lower cost, while retaining the waterproof and weather resistance of chloroprene rubber (can adapt to -20℃ to 80℃ environment), meeting daily use needs.

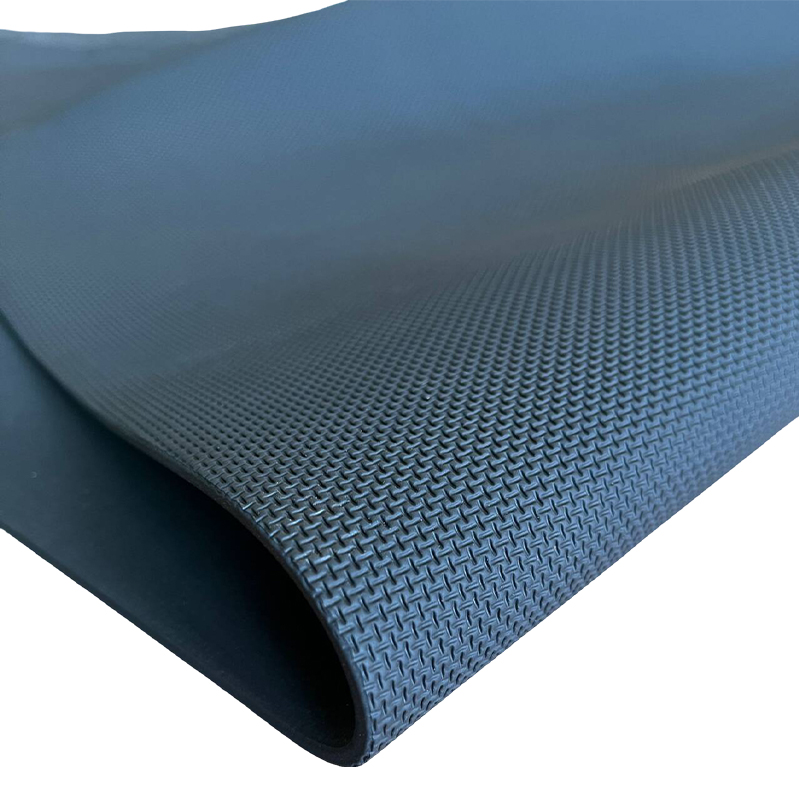

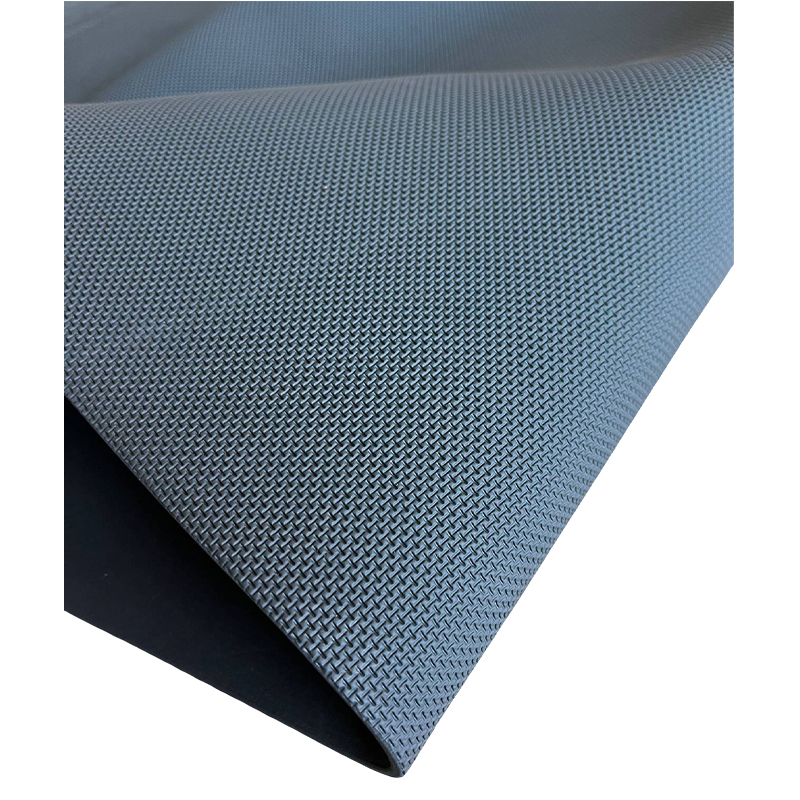

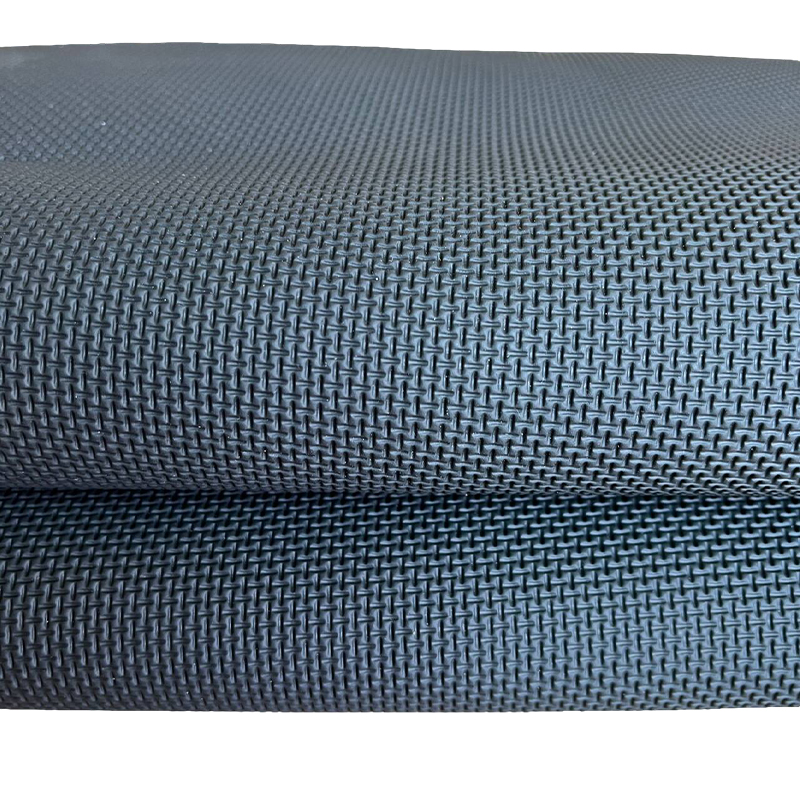

2. Embossing process: coarse/fine texture, double enhancement of function and design

Coarse embossing (strong three-dimensional sense):

Function: The concave and convex texture on the surface enhances the anti-slip property (such as the bottom of bags and the outsole of shoes), reducing the sliding of items; at the same time, it enhances the perception of fabric thickness, suitable for products that require "texture support" (such as tote bags and tool bags);

Application scenarios: outdoor bags, outer layers of shoes, pet mats and other scenes that require anti-slip or three-dimensional shapes.

Fine embossing (exquisite texture):

Function: The delicate texture enhances the touch and visual level of the fabric (such as sportswear cuffs and swimsuit edges), increases the sense of design; at the same time, it reduces the friction between the fabric and the skin, suitable for close-fitting wearing scenes;

Application scenarios: swimwear, tight sportswear, fashionable bag linings and other scenes that require exquisiteness and comfort.

3. Multiple classification and customization, precise adaptation to needs

Hardness classification (mainly SBR type, some other types can be customized):

0-3 degrees: ultra-soft material, with fine embossing, suitable for baby products, thin swimwear lining;

6-8 degrees: medium hardness, coarse embossing is used for sports wrist guards and knee pads to enhance friction and support;

9-11 degrees: relatively hard material, coarse embossing is suitable for bag structure layer and shoe midsole to enhance three-dimensional sense and durability.

Fabric base:

Polyester nylon cotton knitting + coarse embossing: suitable for outdoor bags, taking into account anti-slip and breathability;

Lycra base + fine embossing: used for tight sportswear, improving elasticity and texture design;

OK cloth + fine embossing: medical protective gear lining, skin-friendly and easy to clean.

4. Flexible customization to meet diverse needs

Color customization: support Pantone color card customization or stock color selection (basic colors such as black, beige, etc.), adapt to brand VI or seasonal theme;

Thickness customization: 1-50mm ultra-thin to ultra-thick range, covering from thin swimwear (1-3mm) to thick tool bag support layer (20-30mm);

Flexible size: sheet 1.3*3.3 meters (suitable for small batch proofing), roll material calculated by thickness (support large-scale production), reducing inventory pressure.

Application scenario: from daily consumption to industrial protection, embossing technology empowers all scenarios

1. Consumption scenario: balanced choice of function and design

Bag field: coarse embossed SBR fabric is used for the outer layer of tote bags and backpacks to enhance anti-slip and three-dimensional sense, with brand logo printing to enhance product texture; fine embossed fabric is used for bag lining to reduce the sliding of items and improve the use experience.

Shoe material field: Coarse embossed SBR is used as the midsole or outsole support layer of the shoe material to enhance the anti-slip property; fine embossing is used for the lining of the upper to enhance the touch and breathability, and is suitable for the needs of sports shoes and casual shoes.

Sportswear: Fine embossed SBR + Lycra base is used for swimwear and yoga clothes, and the texture design increases the sense of fashion; coarse embossing is used for sports protective gear (such as knee pads) to enhance friction and support.

2. Industrial and medical scenarios: dual optimization of practicality and cost

Industrial protection: Coarse embossed SBR (9-11 degrees) is used for the outer layer of tool kits and equipment storage bags, which is non-slip and wear-resistant; fine embossing is used for the lining of protective gloves to enhance the grip.

Medical field: Fine embossed SBR + OK cloth base is used for the lining of rehabilitation protective gear, which is skin-friendly and easy to clean, reducing care costs.

3. Pet and fishing scenarios: a combination of durability and practicality

Pet supplies: Coarse embossed SBR is used for the outer layer of pet pads, which is non-slip and easy to clean; fine embossing is used for the inner lining of the traction rope to improve the grip comfort.

Fishing equipment: Coarse embossed SBR (12-16 degrees) is used for the support layer of fishing pants to enhance wear resistance; fine embossing is used for the protective cover of the fishing net to reduce friction with fish.

Our advantages: source manufacturers, economic and efficiency double guarantee

As a source manufacturer focusing on the production of chloroprene rubber fabrics, we provide full-link support for Neoprene SBR Embossed:

Quick response and flexible customization:

Sample service: 1-2 days fast proofing, free within 0.5 meters (reducing customer trial and error costs);

Small batch support: no minimum order quantity (MOQ), suitable for new product development and small batch customization;

Bulk delivery: regular orders are shipped in 3-5 days, and urgent orders can be negotiated to expedite to meet the market's rapid response needs.

Balance between quality and cost:

Controllable materials: SBR fabrics have passed basic performance tests (waterproof, elastic, weather resistance) to ensure compliance with daily use standards;

Price advantage: Large-scale production + direct supply from the source, while ensuring quality, provide competitive prices 20%-30% lower than peers (due to lower SBR costs).

Professional team and reliable packaging:

Technical team: With more than 5 years of experience in the research and development of chloroprene rubber materials, we can provide embossing process selection and material matching suggestions;

Packaging guarantee: The coils are packaged in three layers of "pallet tube + waterproof plastic bag + tear-resistant nylon bag" to ensure that they are not damaged during transportation.